- Solutions by Industry

- by_industry

PLASTICS TESTING

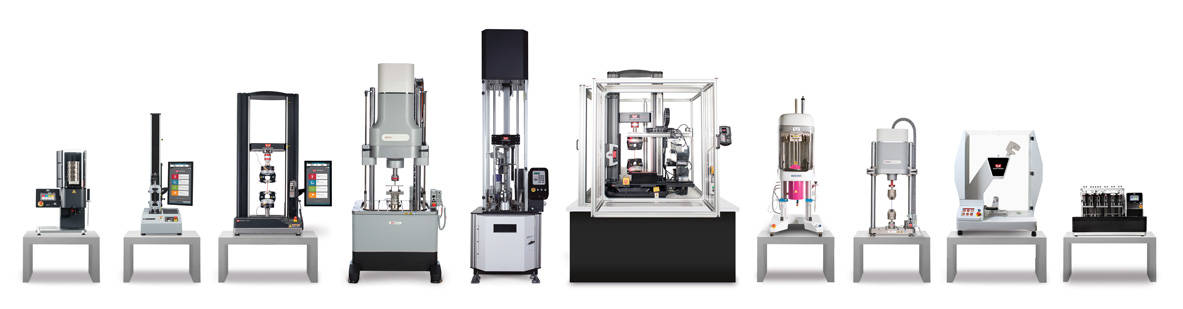

As a global leader in mechanical testing, Instron® partners with many of the world’s largest plastics manufacturers to implement and optimize their testing programs. Our extensive suite of testing equipment enables you to perform all testing necessary to accurately produce and verify material data sheets, including melt flow and HDT / Vicat testers, universal testing machines for tensile, compression, and flexural testing, and Charpy and Izod pendulum systems for puncture impact and tensile impact testing. Our applications experts are well-versed in current plastics standards while our global service organization is ready to provide support to your laboratories at the local level, no matter where they are in the world.

- Applications

- Standards

- Pharmacopeia

- Services / Industry-specific products

- Interesting customer projects

- Downloads

THROUGHPUT AND REPEATABILITY

Many plastics manufocturing envronments requre high volume testing. making them an excelent candidate for utomoton.hough automaion can be adopted at any level. plostics labs fypicaly see the most benefit from robotic or semlrobotic sysfems that can operate for hours with minimal human intervention.

Improving Throughput for Static Testing

Instron’s AT6 and AT3 are fully robotic and semi-robotic options that can be configured for tensile or flexural testing of plastics to a wide range of ISO and ASTM standards. These systems provide high throughput and repeatability while freeing up the operator to perform other value-added tasks. In instances where full automation is not feasible, fixtures such as pneumatic grips, automatic extensometers, and built-in alignment devices - along with software functionality such as choice inputs, also improve throughput while significantly reducing variability in results.

RELATE PRODUCTS

-

Impact Puncture and Tensile

Designed for R&D and advanced quality control, Instron drop weight impact testing machine is used to determine the energy required to break or damage a material from a specific height and with a specific impact energy and velocity.

Learn More -

HDT Vicat

Instron's line of CEAST Thermo-mechanical systems are used to characterize the behavior of plastic materials at high temperatures, measuring their heat deflection temperature (HDT) and Vicat softening temperature.

Learn More -

Impact Puncture and Tensile

Designed for R&D and advanced quality control, Instron drop weight impact testing machine is used to determine the energy required to break or damage a material from a specific height and with a specific impact energy and velocity.

Learn More -

HDT Vicat

Instron's line of CEAST Thermo-mechanical systems are used to characterize the behavior of plastic materials at high temperatures, measuring their heat deflection temperature (HDT) and Vicat softening temperature.

Learn More -

Impact Puncture and Tensile

Designed for R&D and advanced quality control, Instron drop weight impact testing machine is used to determine the energy required to break or damage a material from a specific height and with a specific impact energy and velocity.

Learn More -

HDT Vicat

Instron's line of CEAST Thermo-mechanical systems are used to characterize the behavior of plastic materials at high temperatures, measuring their heat deflection temperature (HDT) and Vicat softening temperature.

Learn More